Dry Ice Cleaning has been rapidly adopted by many industries:

Aerospace and Aviation – Automotive – Engineered Wood Manufacturing – Food & Beverage – Foundry – Medical Device Manufacturing – Mining – Oil & Gas – Packaging – Plastics & Composites Manufacturing – Power Generation – Printing – Rubber & Tires – Textiles

And the list continues to grow….

BUT HOW DOES DRY ICE CLEANING WORK?

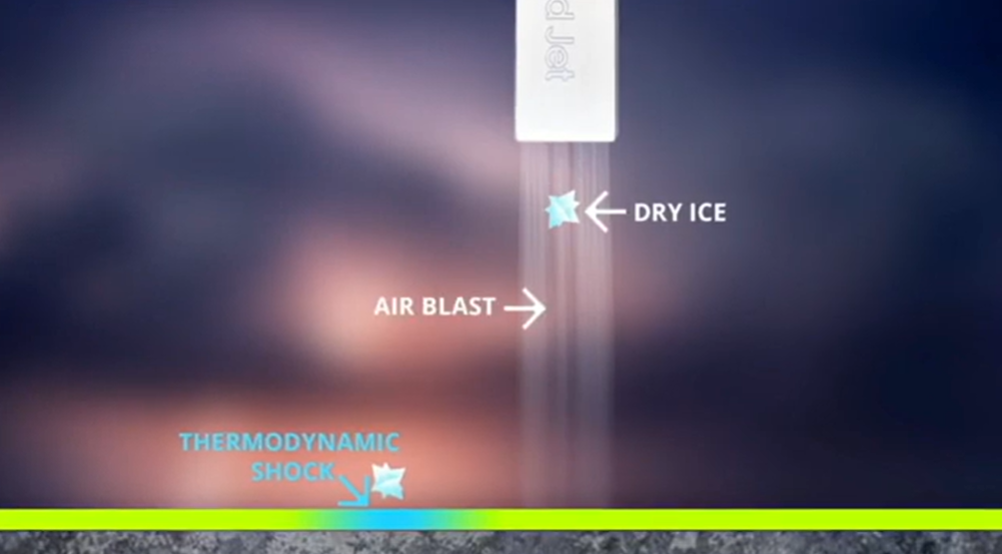

By accelerating dry ice pellets (known as blasting rice for their small size) through a nozzle with compressed air, Dry Ice Blasting Machines combine several cleaning properties at once:

- ABRASIVENESS: Dry Ice is not high on the hardness scale of common abrasives (ice from water is harder!) so it can be accelerated at a high rate of speed to scour without scoring surfaces

- THERMODYNAMIC SHOCK: Dry Ice temperature clocks in a -109 F – instantly freezing and embrittling a contaminant so that it cracks and pulls away from the underlying surface

- CO2 EXPANSION: Dry Ice is really CO2 compressed into a solid state, so a relatively large volume of CO2 gas is packed into each grain of blasting rice. When the rice hits the contaminant, it explosively expands and blows apart the frozen contaminant

- AIR BLAST: High pressure air from an air compressor focused through the nozzle of the Dry Ice Blaster blows the broken contaminant away

Here’s a video of dry ice cleaning at work in the Food & Beverage Industry:

Cold Jet Dry Ice Blasting – Decontamination Food Industry (youtube.com)