Traditionally, removing this burr would be done by hand with files, abrasives or de-burring tools. This process is time consuming, and because it works by removing material, the underlying geometry of a part can be damaged. When that happens, the part must be discarded.

We might picture dry ice blasting as just another way of grinding unwanted metal away, like a sandblaster without water. If that was the case, we would still have the risk of damaging the part being cleaned. So how does blasting with dry ice remove burrs but leave the underlying part undamaged?

WHAT PROPERTY OF DRY ICE MAKES IT SAFE FOR DEBURRING PRECISION PARTS?

Relative Hardness.

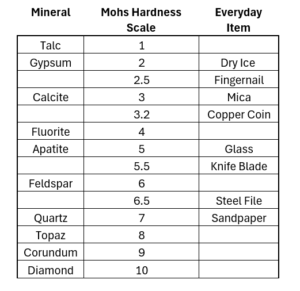

Unlike sand, dry ice is a very soft material. To get an idea of how hard dry ice is, we can compare it to the hardness of other materials. The standard scale for measuring hardness is called the Mohs Hardness Scale. The harder the material the higher the number.

Below is the Mohs Scale with examples of everyday items and their relative hardness:

We can see that sandpaper has a hardness of 7. Dry ice at 2 is even softer than a human fingernail. So how does a material this soft remove a steel burr?

WHAT PROPERTIES OF DRY ICE MAKES IT SO EFFECTIVE AT REMOVING BURRS?

Temperature and Kinetic Energy.

The first property of dry ice that acts on the burr is Temperature. Instead of grinding a burr away, the ultra-low temperature of dry ice “freezes” the thin base of the burr. This rapid temperature change at -109 F. reorders the molecular structure of the material the way freezing temperatures transforms flowing water into ice. The base of the burr that was thin enough to bend and curl under a machining tool is now so brittle that it can crack and shatter like a sheet of ice. Because of its greater mass, the rest of the part cools much more slowly and is unaffected.

The second property of dry ice that acts on the burr is the Kinetic Energy that results from the instant sublimation of the dry ice as it hits the part.

Dry ice is made by compressing and super-cooling CO2 gas into a solid state. A large volume of gas is stored in solid form this way. Under normal conditions, dry ice slowly converts directly into CO2 gas until all the ice has disappeared. This process is called sublimation.

When dry ice particles are accelerated and smash into a surface during dry ice blasting, the entire volume of gas contained in the particle is released at once. The expansion ratio of dry ice to CO2 gas is 1 to 845, so a huge amount of gas is released in an instant. The kinetic energy released in this event is explosive. Combined with the force of the compressed air, the total kinetic energy focused on the embrittled burr breaks it cleanly off at its base.

DOES DEBURRING WITH DRY ICE BLASTING WORK ON PLASTICS?

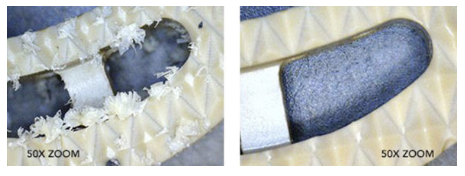

Yes. Dry ice blasting is safe for plastic finishing as well. Though plastics are much softer than metals, they are still harder than dry ice. So the combination of low temperature and kinetic energy can still do the job without damaging the finished part. The image on the left is of a machined plastic part before finishing. The intricate geometries of this part create multiple opportunities for burrs to form. Imagine how painstaking and time consuming it would be to remove those burrs by hand without damaging the underlying surfaces. On the right is an image of this part after deburring with dry ice blasting. We can see there is no damage to the plastic and only clean lines remain.

Here is a video from Cold Jet, the premier manufacturer of dry ice blasters, showing the removal of flash (leftover plastic on molded plastic parts) and burrs from a plastic parts.