Dry Ice Blasting Essentials

Dry ice blasting is a rapidly growing sector of industrial cleaning. Whether you’re tackling fire restoration, automotive detailing, mold remediation, or heavy machinery cleaning, having the right equipment is critical for success. This guide walks you through all the equipment you need to start a dry ice blasting business—plus a list of the top dry ice blasting machine manufacturers.

Core Equipment for Mobile Dry Ice Blasting

1. Dry Ice Blasting Machine

The heart of your operation. Dry ice blasting machines propel dry ice pellets at high velocity to clean surfaces without water, chemicals, or abrasive media. Blasters vary in capacity (how much dry ice they can blast and how hard) so make sure you understand the cleaning requirements of the job, the types of blasters available, and make sure the blaster and equipment will do the job.

Key features to consider:

- Match the capacity of the blasting machine to the job: Industrial cleaning will require higher air pressure (Pounds per Square Inch) and air volume (Cubic Feet per Minute) than car detailing

- Variable pellet size or MicroParticle capabilities: Machines like the PCS series from Cold Jet can change the size of the dry ice particle to match the application. Other machines cannot

- Portability and weight: working in a small shop or on-site in a mobile industrial cleaning application, know what size equipment you’ll be using.

Adjustable blast pressure and blast volume: Most machines offer this ability. However, your options will be limited by the blasting line size and nozzle size offered with a specific model. Smaller air lines and nozzles restrict blast volume (Cubic Feet per Minute), the power of your blaster and caps the cleaning effectiveness of the system.

2. High-Capacity Air Compressor

Dry ice blasting requires a significant air supply. Check the air specifications required by your blaster’s manufacturer and make sure you have enough air in your shop or facility for your blaster. Mobile compressors can run on diesel fuel or use on-site power, and can be towed on site with your equipment or independently. If you are connecting to on-site power make sure you have the right connection for the compressors power requirement.

Recommended specs:

- 135–300+ CFM

- 80–150 PSI

Mobile Compressor: Diesel-powered tow-behind models for mobility can provide the power of installed compressors, but an after cooler is highly recommended

3. After Cooler

Using a portable diesel air compressor, that emits hot and humid air, can affect the quality of your dry ice and hinder the efficiency of your blasting setup. It is recommended to use an after cooler between the compressor and the dry ice blaster to cool the air and eliminate moisture. Moisture in the blaster’s hopper and blasting hose can freeze and cause clogging.

4. Dry Ice Supply and Storage

Most importantly, make sure you have dry ice blasting rice readily available in your area. Blasting rice is not a regular inventory item for Dry Ice Distributors. They will have to put in a special order with their supplier which will add days to your schedule and result in inferior blasting rice. In the Northeast – buy Top Dry Ice Rice direct from the Manufacturer, Top Dry Ice.

Best practices:

- Use insulated dry ice containers or coolers to store the blasting rice. These heavy duty totes hold 500 lbs of dry ice rice and have wheels to easily move around the job site.

- Minimize opening and closing your storage container by utilizing a secondary cooler to hold the rice for re-filling the hopper of your blaster.

- Calculate the amount of dry ice you will need by test blasting the contaminant. Dry ice usage is measured in pounds per minute. Knowing how many minutes it takes to clean a square foot will allow you to order the correct amount of dry ice for the job.

Other Equipment

4. Hoses and Blasting Nozzles

Make sure your blasting hoses will reach from your blaster to all the areas you need to clean. You may need to get longer than standard hoses. The air hose from the compressor to your blaster must provide the CFM required for your job. If the diameter of the air hose is too small, it will choke the airflow and result in poor performance. Blasting Nozzles are designed for specific tasks – have the right size nozzle for your application..

5. Personal Protective Equipment (PPE)

Protect your crew and meet safety regulations with:

- Safety goggles or face shields

- Hearing protection

- Insulated gloves (dry ice is -109°F/-78.5°C!)

- Respirator masks in confined or mold-heavy environments

Mobile Setup: Going On-Site

To deliver professional mobile dry ice cleaning services, you’ll need to transport your equipment efficiently::

- Box truck or enclosed trailer secure and lockable with all equipment safely stowed for transportation or onsite storage

- Ramp or lift system for loading/unloading equipment

Ventilation, lighting, containment/tenting Dry Ice Blasting leaves no residue, but the contaminants you will be removing will land on other surfaces. You may need to contain your blasting area to keep the rest of the home or facility clean. Be sure to set up proper ventilation and make sure your area is well lit.

Dry Ice Blasting Machine Manufacturers and Rental Companies

Choosing the right manufacturer can make a significant difference in performance, durability, and technical support. Here’s a list of leading dry ice blasting machine manufacturers:

Manufacturer

Notable Features

Market leader, MicroParticle technology – “Particle Control System” (PCS), high-end industrial models

Dry Ice Blasting Solutions – Dry Ice Blasting & Cleaning – Dry Ice Blasting Equipment Manufacturer | Cold Jet

Machines: Aero 2 PCS Ultra, Aero 2 PLT Ultra, Aero 2 PCS 60, Aero 2 PLT 60,

Aero 40 FP, Aero 80 FP, Aero C100, E-CO2 150, Elie 20, i3 Microclean, i3 Microclean 2 IceRocket PLT, SDI Select 60, Xcel 6

Portable models, mid-tier price points

Dry lce Blasting Machine Archives – AUTOOL

Machines: Autool HTS705, Autool HTS708, Autool HTS709

Automotive Cleaning and Detailing

Dryce Automotive Dry Ice Cleaning

Machines: Autool HTS705, Autool HTS708, Autool HTS709

Industrial Sized Machines

Dry Ice Blasting Equipment and Machines Built by Phoenix Unlimited LLC

Machines: Phoenix PHX-150, Phoenix PHX-200, Phoenix PHX-250, Phoenix PHX-539

Industrial Sized Machines

Nu-Ice Dry Ice Blasting – Dry Ice Cleaning Machines

Machines: Commando XP Blaster, Commando 35 Blaster, Commando 40 Blaster, Commando 55 Blaster, Commando 80 Blaster

Industrial Cleaning Machine Manufacturer

Dry Ice Cleaning – Kärcher

Machines:IB 7/40 Advanced, IB 15/120 ADV,

Car Detailing Specialists

Dry Ice Cleaning – professional tech-advanced cleaning machines – SANITMAX

Machines: SM1000, SM2000

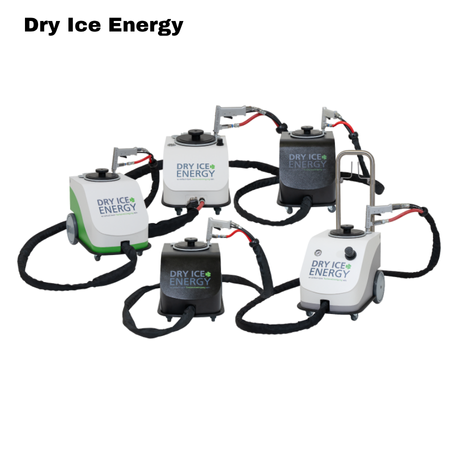

Small and Medium size machines

DRY ICE ENERGY product overview – everything at a glance

Machines: Champ Basic, Champ, Champ Turbo, Champ Vario, Champ Turbo Pro, Champ, Champ Ultra

RENTAL OPTIONS

| Check the location where you would like to rent in advance to make sure they have the blaster in current inventory |

Red-D-Arc

| Blasters, Air Hose, Blasting Hoses, Nozzles, After Coolers Dry Ice Blasting Equipment & Expertise I Red-D-Arc Machines: CHECK WITH LOCAL DEALER FOR AVAILABILITY. Cold Jet Aero 40, Cold Jet Aero 80, Cold Jet 400 P/E After Cooler, Nu-Ice Commando 55, Nu-Ice Command Air 500 Aftercooler |

Sandblast Solutions

Machines: CHECK WITH LOCAL DEALER FOR AVAILABILITY. Cold Jet Aero 40FP, Cold Jet 400 P/E After Cooler

Sandblast Solutions – sandblast solutions

United Rentals

Machines: CHECK WITH LOCAL DEALER FOR AVAILABILITY. Cold Jet Aero 40FP,

Dry Ice Blaster for Rent – United Rentals

Sunbelt Rentals

Machines: CHECK WITH LOCAL DEALER FOR AVAILABILITY. Cold Jet Aero 40FP,

Dry Ice Blaster 40# | Sunbelt Rentals