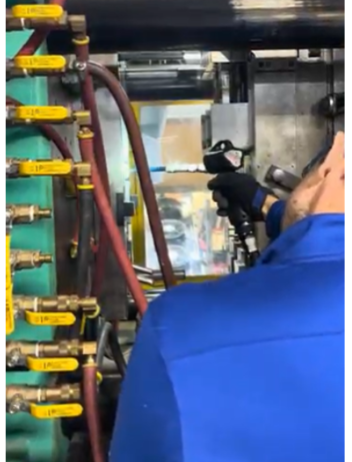

Maintaining manufacturing equipment is a challenging task. Ensuring operational efficiency requires regular maintenance and cleaning, which often leads to downtime and high costs. However, Dry Ice Blasting has emerged as a revolutionary solution for industrial equipment maintenance. This non-abrasive, eco-friendly cleaning method offers multiple advantages over traditional techniques like sandblasting and chemical cleaning. Below are five key reasons why manufacturers prefer dry ice blasting for equipment maintenance.

1. Minimal Equipment Downtime

One of the biggest concerns in industrial settings is reducing downtime during maintenance. Traditional cleaning methods require equipment shutdowns for hours or even days. However, dry ice blasting offers:

✔ In-place cleaning (without dismantling machinery)

✔ Reduced maintenance windows

✔ Immediate return to production

2. Zero Secondary Waste Generation

Unlike sandblasting or chemical cleaning, Dry Ice Blasting Product does not produce secondary waste. The dry ice pellets sublimate (turn directly into gas) upon impact, eliminating waste disposal costs.

Key benefits include:

✔ No leftover residue or chemicals

✔ Reduced environmental compliance challenges

✔ No need for additional cleaning of waste materials

3. Safe for Electrical Components

Manufacturing machinery contains delicate electrical and electronic components that require specialized cleaning. Dry ice blasting is ideal for such applications because:

✔ It uses no water or solvents, preventing short circuits

✔ It preserves electrical shot circuits

✔ It is non-abrasive, ensuring sensitive components remain undamaged

This makes dry ice blasting an excellent choice for cleaning control panels, circuit boards, and electrical cabinets.

4. Improved Cleaning Efficiency

Dry ice blasting can effectively clean various materials that traditional methods struggle with. It removes stubborn contaminants like grease, oil, adhesives, and rust without requiring harsh chemicals.

Additional advantages:

✔ Reaches complex geometries and hard-to-access areas

✔ Replaces time-consuming hand-cleaning procedures

✔ Cleans metals, soft plastics, and rubber parts while still assembled

5. Extended Equipment Lifespan

Since dry ice blasting is a non-abrasive cleaning technique, it does not damage the surface of the equipment. This helps manufacturers protect their investment in expensive machinery by:

✔ Preventing surface degradation

✔ Preserving original equipment specifications

✔ Reducing long-term replacement costs

Regular use of dry ice blasting contributes to a longer lifespan for industrial equipment, making it a cost-effective solution in the long run.

Conclusion

Dry ice blasting has become the go-to cleaning method for manufacturers seeking a safe, efficient, and eco-friendly way to maintain their equipment. By minimizing downtime, eliminating secondary waste, ensuring safety for electrical components, improving cleaning efficiency, and extending the lifespan of machinery, this innovative technique provides significant advantages over traditional cleaning methods. For industries that rely on operational efficiency, adopting dry ice blasting can lead to long-term cost savings and improved performance.